The problem:

The manufacturing industry faces well-defined cost and energy challenges in the mass production of metal parts. With global competition and price pressure, there is an increased demand for a reduced cost per produced part. Today the manufacturing industry spend significant amounts on material waste, in normal production 20 – 50% of the total raw material.

The solution:

With Tomologic’s patented clustering technology it is now possible to reduce costs and increase output while maintaining product quality. By arranging parts as clusters and carefully planning the cutting path, production reliability is maintained while reducing the total cutting length. Machine operator expert knowledge combined with state of the art artificial intelligence technology is the foundation of our innovative and disruptive optimization service.

Tomologic takes end-to-end control over the optimization process, from part placements in clusters to cutting path optimization. Maintaining reliable production implies taking into account all physical constraints in the cutting process, such as: heat, tension, melting, tilting parts, inductive cutting, struggling sheets etc. All these factors are part of our optimization model making it computationally intensive and requiring high performance computing.

Using the Software as a Service delivery model means clear benefits for all stakeholders. Learn how: Manufacturers, Machine Builders

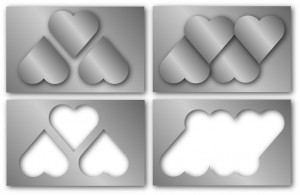

To the right: Tomologic’s intelligent processing without inter-part safety distance.